Researchers at MIT’s Self-Assembly Lab have come up with a novel way to overcome one of the biggest existing drawbacks with 3D Printing.

THE PROBLEM

In short, the problem is speed. 3D printing has almost always been a slow process.

THE SOLUTION

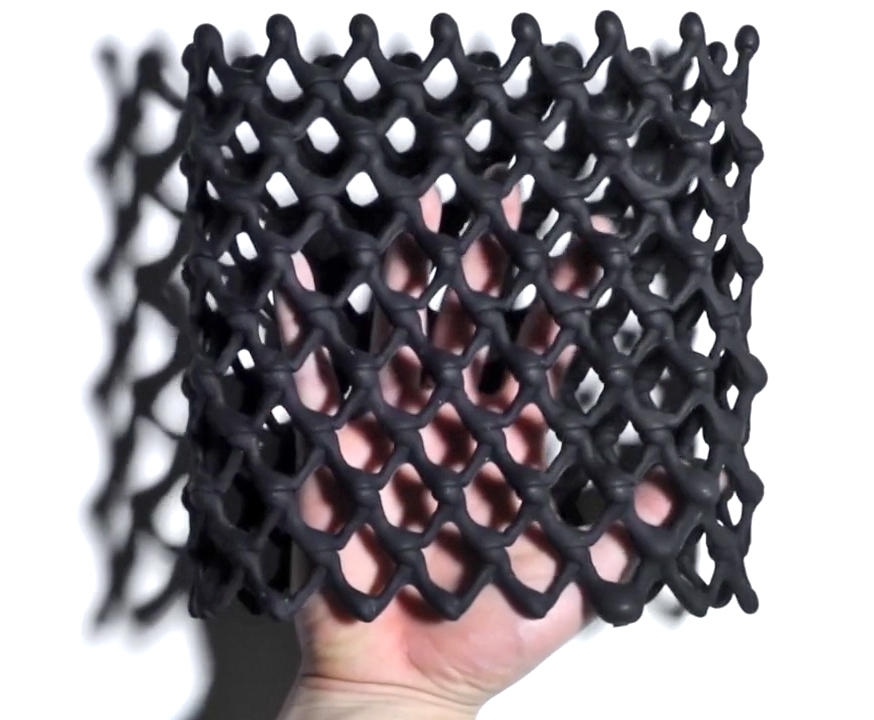

Scientists at MIT, working with furniture maker Steelcase and materials researcher Christophe Guberan, have developed a new 3D printing process that is potentially much faster. The team have printed an object in just 10 minutes that would have taken 50 hours to print using a traditional 3D printer.

THE APPLICATIONS

Without the limitations of gravity, 3D printers should be able to manufacture complex objects in a single pass, including gears, wiring, and other moving components, without requiring the assembly of hundreds of different parts afterwards.